OXYGEN

MEASURING AND CONTROL

Stationary

oxygen measuring and controlling

TECHNICAL DETAILS TRANSMITTER UNIT: |

||

| Measurement | 36 x 16 x 31 cm | |

| Connection voltage | 220 VAC, 110 VAC, 24 VAC, 24 VDC | |

| Protection | IP 55 | |

| Accuracy | +/- 0,2 mg/l | |

| External Signal | 0-20 mA | |

| Load | 600 Ohm | |

| Display | digital display | |

| Relays | All relays are simply reversed from NC to NO All relays easily switches from NV to NO. | |

| External contact : | potential free | |

| Oxygen

Measurer PLC A PLC with a maximum of 64 measuring points: with this device you can measure and regulate oxygen, pH ,temperature etc. It is a small and powerful PLC that works in conjunction with modules. The main-unit accepts 64 analog input-signals, has four contact(alarm) inputs and two contact outputs. The PLC measures, regulates and warns. Parameters are adjustable for each channel. De PLC has the possibility to register data en log it. The PLC can be connected to a personal computer. In collaboration with a personal computer you can work with graphical representations of your system. For instance you can display: probes, valves and pumps.

|

|

|

| On the display you can view recent values and next to them all kinds of boundary values that you can manually adjust. | ||

|

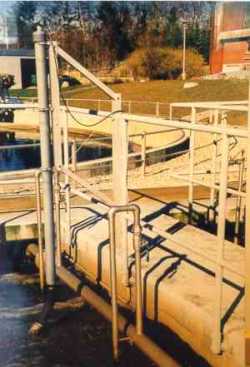

Special Measuring Units: 1. The 840 measure and regulating system as seen on the left picture is a system for extreme circumstances. The main-unit consists of the following parts:

2. The PPB system that measures micrograms per liter. Specially made for measuring water that has to be clean of oxygen. For example: hot water heater , condensate en heating-water. 3 The PPB hygienic system, a variant of the previous model. Is specially developed for the dairy an nutrition industry 4. Special unit to measure atmospheric oxygen. |

|

![]()

| Multivis

Waterbehandeling B.V.. Waterbehandeling-Wastewatertreatment J.P. Santeeweg 1 9312 PB Nietap, The Netherlands |

e-mail: |

j.meindersma@multivis.nl +31 (0) 594 516748 +31 (0 )594 512905 |

Copyright

© 2002 Multivis |